In highly regulated industries—such as aerospace, medical device manufacturing, pharmaceuticals, defense, automotive, and advanced electronics—the accuracy of measurement equipment directly affects product quality, safety, and compliance. Regulations from the FDA, FAA, DoD, ISO, and other governing bodies require organizations to maintain strict control over equipment calibration, traceability, documentation, and measurement uncertainty. This is where SIMCO’s calibration advantage becomes particularly significant.

SIMCO provides comprehensive, scalable calibration solutions designed specifically for the needs of regulated industries. Their approach emphasizes consistency, traceability, risk management, and documentation excellence—resulting in reliable measurement systems across entire enterprises.

Why Regulated Industries Need a Superior Calibration Partner

Equipment calibration is not simply a technical service; it is a foundational element of a regulated quality system. Poor calibration control leads to:

- Audit findings and nonconformances

- Data integrity issues

- Product recalls

- Process drift

- Safety risks

- Loss of supplier qualification

Regulated environments demand a calibration provider that delivers more than individual instrument calibration—they require end-to-end program management.

SIMCO’s calibration infrastructure meets this demand by combining accredited calibration methods with multi-site consistency and robust documentation practices tailored to high-stakes environments.

** SIMCO’s Key Advantages for Regulated Sectors**

1. Enterprise-Wide Standardization

SIMCO ensures that every site within a multi-facility organization receives the same calibration quality, the same procedures, and the same documentation format. This eliminates variation that can arise when using multiple local or inconsistent calibration vendors.

Their distributed laboratory network enables organizations to implement standardized calibration programs across regions while maintaining full traceability.

2. Deep Scope Across Calibration Disciplines

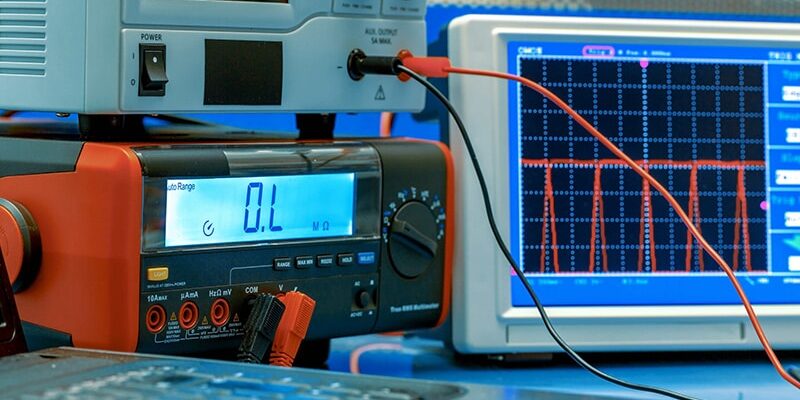

Regulated industries use diverse measurement equipment—from dimensional gages to advanced electronics, torque tools, environmental sensors, and radiation measurement devices. SIMCO supports this complexity with an extensive calibration scope, including:

- Electrical and electronic test equipment

- Dimensional and mechanical instruments

- Temperature and humidity sensors

- RF, frequency, and signal devices

- Radiation and safety instrumentation

- Torque and force measurement tools

Organizations with distributed operations can benefit from SIMCO’s nationwide coverage through its calibrated laboratory network, which supports consistent service delivery across all corporate sites.

3. Regulatory-Focused Documentation

Calibration certificates must withstand regulatory scrutiny. SIMCO’s documentation aligns with audit expectations and typically includes:

- As-found and as-left measurement data

- Calibration status

- Traceability to national standards

- Environmental conditions

- Measurement uncertainty

- Technician identification

- Clear asset information

This type of documentation is essential for passing ISO, FDA, FAA, and customer audits.

Organizations seeking broad calibration oversight often rely on SIMCO’s comprehensive calibration program management, which provides systemwide control, asset visibility, and audit-ready reporting.

4. Risk-Based Calibration Strategies

Regulated industries frequently implement risk-based calibration intervals based on:

- Equipment function

- Product impact severity

- Historical drift behavior

- Regulatory requirements

- Environmental and usage factors

SIMCO assists with calibration interval determination using data-driven methods, ensuring equipment remains compliant without unnecessary downtime.

5. Full Traceability and Measurement Uncertainty Control

Regulated industries must prove that measurements are:

- Accurate

- Repeatable

- Traceable

- Scientifically valid

SIMCO’s accredited processes and validated calibration procedures provide defensible measurement uncertainty, supporting decision-making during inspections, product verification, and process qualification.

How SIMCO Supports Audit Readiness

SIMCO’s calibration services prepare organizations for:

- FDA inspections

- ISO/IEC 17025, ISO 9001, and ISO 13485 audits

- AS9100 evaluations

- Department of Defense oversight

- Supplier and customer quality audits

Their consistent labeling, calibration certificates, and asset tracking systems ensure that every instrument is:

- In calibration

- Properly documented

- Easily traceable

- Audit-defensible

This level of reliability reduces audit risk and improves operational confidence.

Industry Examples of SIMCO’s Calibration Advantage

Aerospace and Defense

Precision measurement is mission-critical. SIMCO provides calibration that aligns with AS9100 requirements and supports high-reliability applications.

Medical Device and Life Sciences

Calibration must support GMP expectations and validation requirements. SIMCO’s documentation and traceability align with ISO 13485 and FDA QSR.

Automotive Manufacturing

IATF 16949 emphasizes measurement system analysis and calibration traceability—areas where SIMCO excels.

Pharmaceutical and Biotech Manufacturing

Process instrumentation calibration directly affects product quality and safety, requiring traceable and auditable calibration systems.

Conclusion

SIMCO delivers measurable value to regulated industries by providing consistent, accredited calibration, robust documentation, multisite harmonization, and complete program control. In environments where measurement error can lead to compliance issues or safety risks, SIMCO’s calibration advantage enables companies to operate confidently, efficiently, and in full accordance with regulatory requirements.